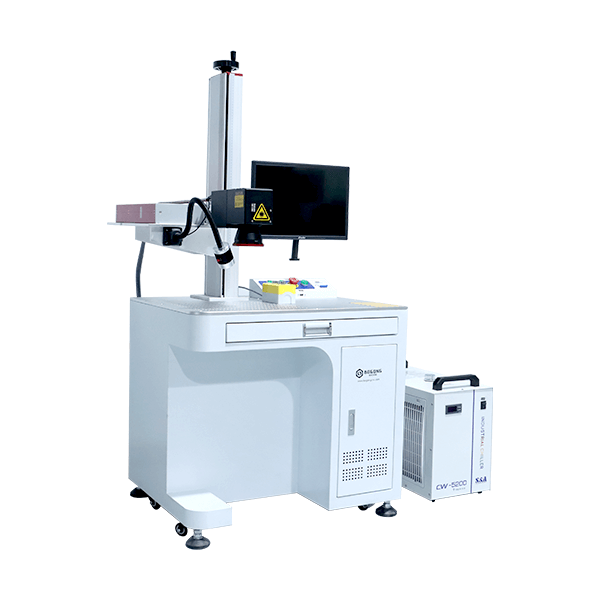

CO2 laser marking machine Introduction:

BOGONGCNC’s CO2 laser marking machine has a portable integrated design, which saves space and is easy to move. The marking machine is equipped with a machine tool light, which significantly improves the accuracy of marking and work safety, and has a positive impact on improving overall production efficiency and quality.

Our CO2 laser marking machine uses Davi laser and RC1001 servo motor, which can perform high-precision laser marking with high speed and pollution-free characteristics. CO2 laser marking machine can process a variety of materials, including bamboo products, wood, paper, leather, glass, textiles, acrylic and product packaging, etc.

CO2 laser marking machine demonstration video

Technical parameter display

|

Model

|

CO2 Laser marking machine

|

|

Laser type

|

CO2

|

|

Laser power

|

60w DAVI

|

|

Max marking speed

|

7000mm/s

|

|

Graphic formate supported

|

PLT, BMP, JPG, PNG, TIP, PCX, TGA, ICO. DXF,etc

|

|

Beam quality

|

< 1.2

|

|

Pulse repeat frequency

|

0-25KHZ

|

CO2 laser marking machines are widely used in various industries for creating precise and permanent marks on a range of materials. Here are some of their key advantages and features:

Advantages:

1.Versatility: CO2 lasers can mark a variety of materials, including plastics, wood, glass, leather, and certain metals (often through the application of marking sprays). This makes them suitable for diverse applications.

2.High Precision: The laser provides high-resolution markings with exceptional detail, enabling intricate designs and small text to be marked accurately.

3.Permanent Marking: The marks produced are typically durable and resistant to fading, making them ideal for branding, product identification, and traceability.

4.Speed: CO2 laser machines can operate quickly, significantly reducing cycle times compared to other engraving methods, which boosts productivity.

5.No Contact Required: The non-contact nature of laser marking eliminates the risk of damaging the material, as there’s no physical tool making contact with the workpiece.

6.Low Operating Costs: Once installed, CO2 laser machines have low maintenance costs and minimal operating expenses compared to traditional marking methods.

7.Eco-friendly: CO2 lasers do not produce hazardous waste, making them more environmentally friendly than some chemical-based marking methods.

8.Ease of Use: Many CO2 laser marking systems come with user-friendly software and control interfaces, making them accessible even for users with limited technical expertise.

Features:

1.Software Compatibility: CO2 laser markers are compatible with various graphic design software, which allows for easy creation and manipulation of designs.

2.High-Speed Galvo Scanners: Many systems are equipped with fast galvanometer-driven scanners that enable rapid movement and marking speeds.

3.Adjustable Power and Speed Settings: These machines typically allow for the customization of power and speed settings to accommodate different materials and desired marking depths.

4.Cooling Systems: To maintain performance and prolong the life of the laser, many CO2 laser marking machines are equipped with efficient cooling systems.

5.Integrated Communication Interfaces: Most models support various communication interfaces, making integration into existing production systems easy.

6.Compact Design: Many units are designed to be compact, making them suitable for a variety of workspace environments, including small shops.

7.Safety Features: CO2 laser machines often include safety features such as enclosures and emergency stop buttons to protect operators during use.

Applications:

1.Product Marking: Serial numbers, barcodes, and logos on products.

2.Industrial Manufacturing: Parts marking for tracking and quality control.

3.Personalization: Custom engraving on gifts, awards, and personal items.

4.Medical Devices: Markings on surgical instruments and medical products for compliance and traceability.